Products

We provide not only equipment sales, but also specific operation methods to meet the site conditions, needs and post-processing requirements. We also offer specific operation methods per your requirements. We will introduce products that meet the customer’s needs and challenges.

Select a Purpose

recommended for those who have these problems

- significant drip loss

- Desire to reduce food loss

- poor quality after thawing

- desire to stop thawing under running water

- issues with thawing depending on the season

- long thawing time and issues with storage

- slicing and grounding frozen ingredients doesn’t work well

- desire to level the workload

- refrigerator thawing is time-consuming

- worker shortage

Case 01

- significant drip loss

- Desire to reduce food loss

- poor quality after thawing

- desire to stop thawing under running water

Challenges

- Desire to stop thawing under running water because of wastewater treatment

- Significant drip loss after thawing, and the floor gets dirty

- Difficult to use due to inconsistency in quality after thawing

Solution

- With DEPAK thawing, put food in the chamber and thaw with a touch of a button

- DEPAK thaws food with minimal drip loss and high quality

- Uniform and even thawing achieved by controlling temperature and air volume

Go to Product Page

Case 02

- issues with thawing depending on the season

- long thawing time and issues with storage

- desire to level the workload

- refrigerator thawing is time-consuming

- worker shortage

Challenges

- Difficulty defrosting in the winter

- Refrigerator thawing takes significant time

- Due to long thawing times, there are also storage difficulties

- Worker shortage

Solution

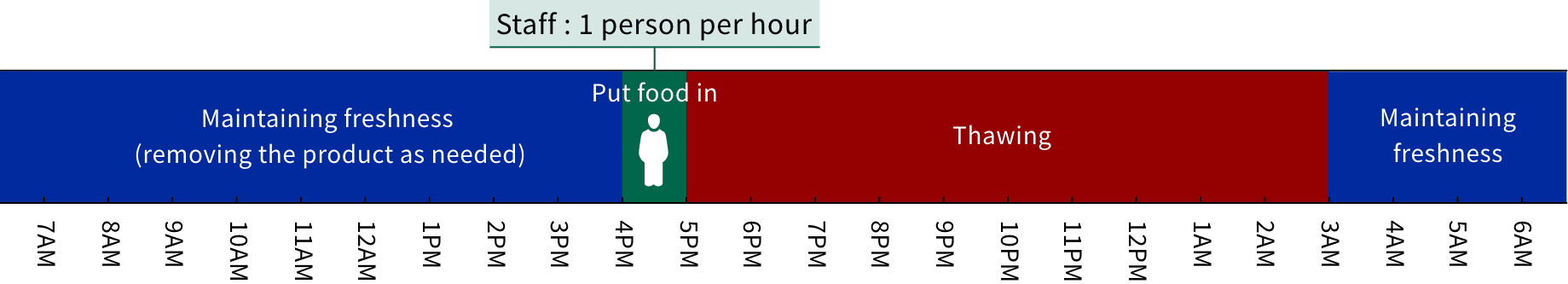

- Stable thawing regardless of the season

- Reduce thawing time by controlling temperature and air volume

- If raw materials are put in in the evening, thawing will be completed by the next morning, so there is no need for extra storage space.

- After thawing, it automatically switches to freshness preservation mode, reducing amount of labor required to transfer materials to another location, and allowing for holidays.

Example DEPAK thawing operation time

Go to Product Page

Case 03

- slicing and grounding frozen ingredients doesn’t work well

Challenges

- Wasted sliced meat

- Ground meat turns white

- Meat surface melts and needs tempering

- Variation depending on the season

cut into slices after thawing

grounding after thawing

Solution

Even temperature for all materials

- Improved slice yield

- Better finishing of ground meat

- No need for tempering

- Stable thawing all year round

cut into slices after thawing

grounding after thawing

Go to Product Page

Case 01

- Desire to reduce food loss

- Desire to stabilize procurement

Challenge

- We want to stock up when it is cheap, but it is hard to store.

- Ingredients do not last long

After 21 days storage

Solution

- Ingredients can be stocked in bulk at inexpensive prices because they can be kept longer.

- Depending on ingredients, some ingredients last twice as long as conventional refrigerators. This contributes to a reduction in food loss

After 21 days storage

- SS Series-

Go to Product Page

Case 02

- Desire to age food

- Desire to distribute workload

- Shortage of workforce

Challenge

- Not enough part-time workers to prepare food when busy

- Must work on days off because the food doesn’t last long

- Not able to use up cut ingredients

Solution

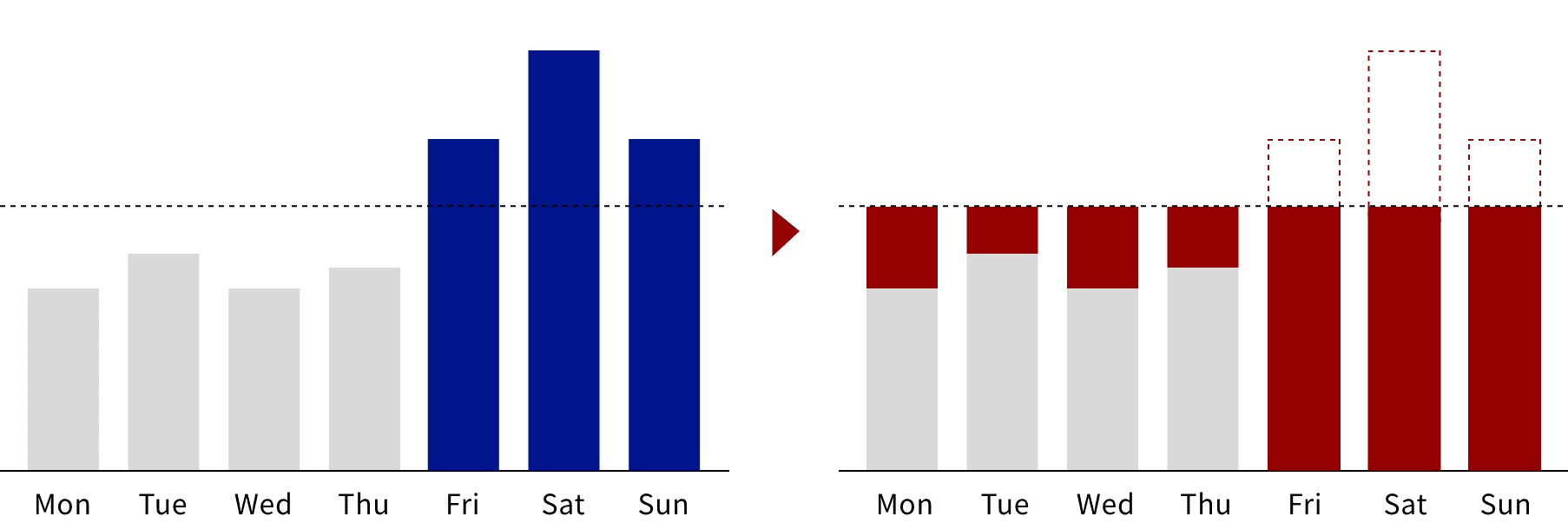

- Since the DEPAK effect keeps ingredients fresher longer, it makes possible to do bulk preparation on weekdays when time is available.

- The DEPAK effect reduces discoloration and order while maintaining freshness, thus reducing food loss.

(example) In the case of a grilled meat restaurant.

Sliced and cut meat can be stored for 3 to 5 days, allowing for bulk preparation during weekdays when time is available for busy weekends.

Reduced workload on weekends. The flavor of ingredients is increased and aging progresses.

Work on weekdays for busy weekends Preparation work can be spread evenly

- SS Series-

Go to Product Page

Case 01

- Want to freeze food

- Want to equalize workload across different days

- Want to increase sales

- Want to reduce waste

- Want to stabilize stock

Challenges

- Wanted to freeze quickly

- Wanted to improve the quality of freezing

- Wanted to start a mail order business

- As it is hard to use many items every day, wanted to make them at once

Solution

- Reduces time with quick freezing

- Allows for high quality freezing by minimizing damage during the freezing process

- Because of its good quality after thawing, it is also good for selling frozen ingredients

- By freezing prepared ingredients, cooking and serving can be done easily, allowing for increased to work efficiency

Go to Product Page