Advantages

Our products using Santetsu Engineering’s proprietary technology DEPAK offer a variety of advantages in terms of food quality, work efficiency, and hygiene control.

Here are some of the advantages of our products that have satisfied many of our customers.

What is DEPAK

The brand name for a high-voltage electrostatic induction thawing machine developed by Santetsu Engineering.

Everything deteriorates through oxidation, which is why we’ve made it our focus for research and development.

Using electrical energy produced by a DEPAK charger, the cell activation and anti-oxidation effects of DEPAK have the following effects.

- Reduce drip loss and increase yield.

- Food can be stored for a long time without discoloration and deterioration.

- Long-term storage increases flavor and allows aging and ripening to occur at a low temperature.

- Low-temperature storage suppresses the growth of bacteria by reducing drip loss.

Advantages of DEPAK Products

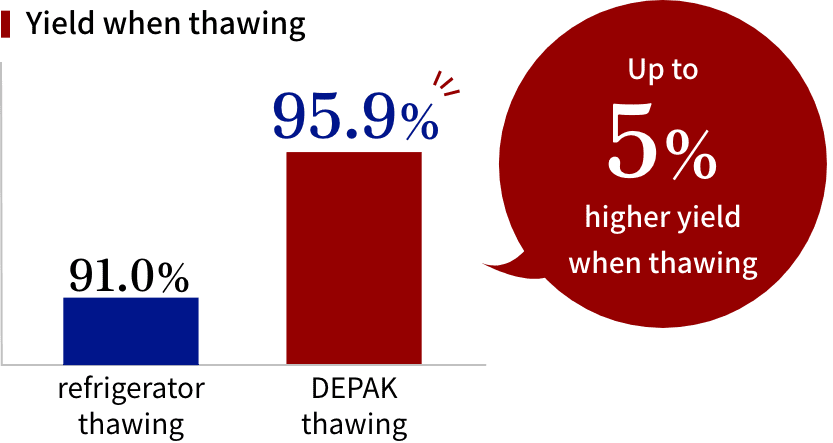

Yield Improvement

Prevent drip loss

With typical thawing methods, a large temperature difference is created between the surface and center of the food during the process of heat exchange from the food surface, and thawing is not even. This is because the ice crystals of the partially thawed water damage the cell membrane, causing fluid containing nutrients and delicious taste to flow out as drip loss.

By using our proprietary technology DEPAK, we reduce the deterioration of cell membranes by thawing each cell evenly. This suppresses the cell destruction due to changes that occur as fluid in food changes between liquid and solid during freezing and thawing. This allows efficient thawing with minimal temperature differences even in low temperature environments, thereby reducing stress on ingredients and greatly reducing drip loss.

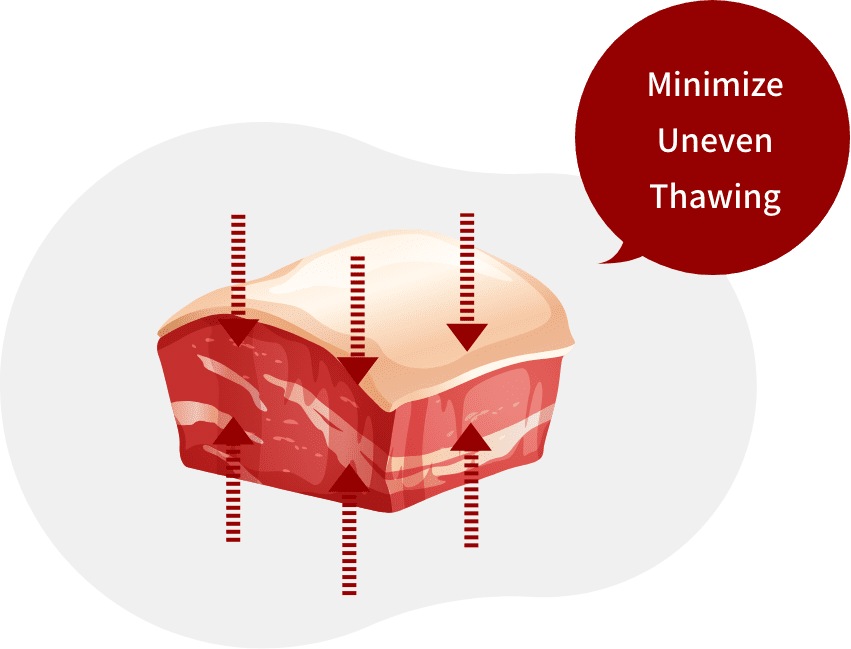

Uniform Thawing

Smooth post-process

There are various methods for thawing, such as refrigerator thawing, running water thawing, and microwave thawing. When thawing, it is sometimes very difficult to control the degree of thawing, as the surface may be too thawed, while the center may not be thawed enough.

DEPAK and temperature and air control enable uniform thawing of the food to its core.

DEPAK thawing solves the problems of inconsistent thawing due to seasonal variation in thawing conditions. Conventional thawing methods cause unevenness and hardness in the center, making it difficult to slice.

Improve Work Efficiency

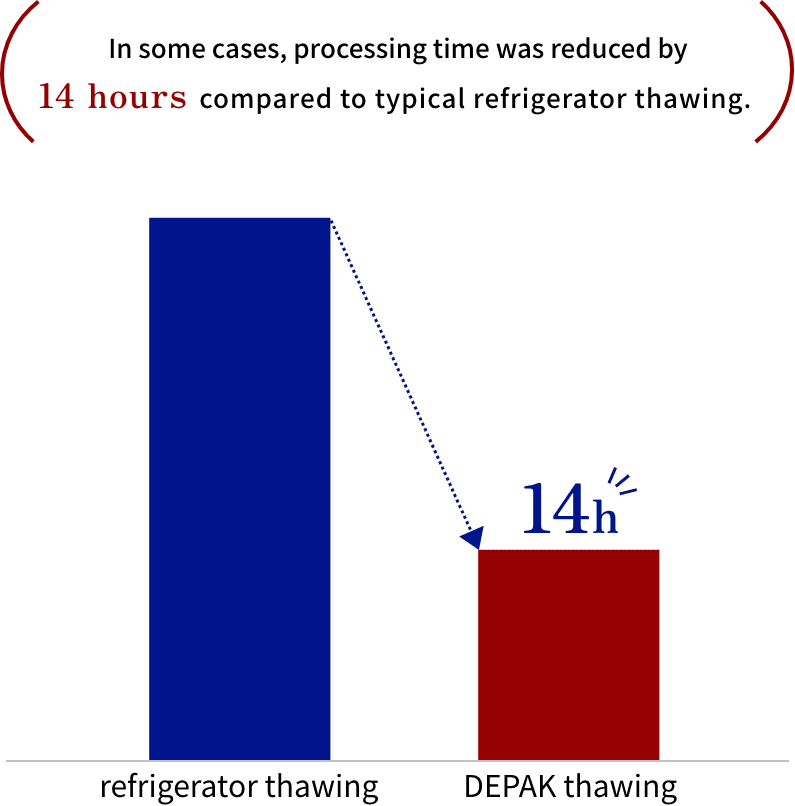

Shorten thawing time while preserving taste

Refrigerator thawing is generally considered to be hygienic, with minimal drip loss, because refrigerator thawing can be done slowly at a low temperature while minimizing the temperature difference between the surface and center of the food. However, it has the disadvantage of taking a long time to thaw.

Conversely, thawing in running water takes a shorter time than other thawing methods, but the temperature difference between the surface and the center of the food is large, and the original taste and umami of the food is lost. In addition, there can be hygiene risks due to the inflow of water.

DEPAK thawing controls precisely calculated temperature and airflow in a low temperature environment similar to that of a refrigerator, and the DEPAK effect reduces the temperature difference between the surface and the center of the food. The DEPAK thaws food in approximately half the time of a conventional refrigerator without losing the original umami and flavor of the ingredients.

By establishing a stable operation that is not affected by the season or temperature, it is possible to reduce the inventory burdens and respond to unexpected orders.

Easy operation that automatically switches to freshness preservation after thawing

Put the ingredients in the thawing chamber and start thawing with the touch of a button. Once the food is thawed to the desired temperature, it automatically switches to freshness preservation mode, which is similar to a low-temperature refrigerator. This eliminates the need for transferring food after thawing, making it possible for anyone to use it and ensuring stable thawing all year round.

Improved Sanitary Environment

Stain resistant and easy to wash

Thawing is performed in a low-temperature environment with minimal drip loss, so the floor remains clean, dry, and hygienic. Daily cleaning and maintenance are also easy. It also has excellent washability.

In addition, since machine uses only electricity for its function, the running cost is only the monthly electricity bill.

Please let Santetsu Engineering help to improve the on-site hygienic environment and HACCP compliance at your plant or company.

DEPAK thawing helps create a neat and clean on-site environment.

Quality Improvement

Prevent Oxidation

Oxidation of ingredients in food deteriorates its quality, flavor, and nutritional value. For example, the oxidation of color and flavor in food affects its color and aroma, resulting in loss of quality. In this way, food deteriorates due to oxidation.

In general, once a food has been oxidized, it will never return to its original fresh state. In other words, it is important to prevent the progress of food oxidation to preserve the original taste and freshness of food.

Our proprietary DEPAK technology creates a slightly alkaline environment that is also high in negative electrons, thereby suppressing oxidative deterioration of the food.

By thawing food while preserving its original taste and umami preservatives and additives can be reduced. In addition, by reducing drip loss during thawing, shrinkage during cooking can be minimized and yield after heating can be greatly improved

Products with DEPAK

Please look at our products using our original technology “DEPAK”

Go to Product Page