What is “DEPAK”

The quality of the food is reflected in its appearance

Proprietary “DEPAK” technology by Santetsu Engineering

This system activates cells and suppresses oxidation by applying a high-voltage weak current to food.

Many customers are amazed at the quality of the food when they see it thawed using this technology, it is hard to believe that it was once frozen.

Thawing with DEPAK reduces drip loss. Drip loss occurs when cells are damaged by ice crystals, and water and nutrients flow out of them during thawing.

In other words, its appearance is directly related to quality.

In addition, it contributes to on-site sanitation, reduced thawing time, and reduced food loss. Not only is it delicious, but it also contributes to reducing management issues and furthering progress for SDGs.

The future of food begins with Santetsu Engineering’s thawing machines.

Advantages

Our proprietary “DEPAK” technology enables freezing, thawing, and storage of food without compromising its freshness.

By suppressing cell destruction and reducing drip loss, it not only preserves flavor, but also contributes to increased work efficiency, reduced labor costs and improved sanitary conditions.

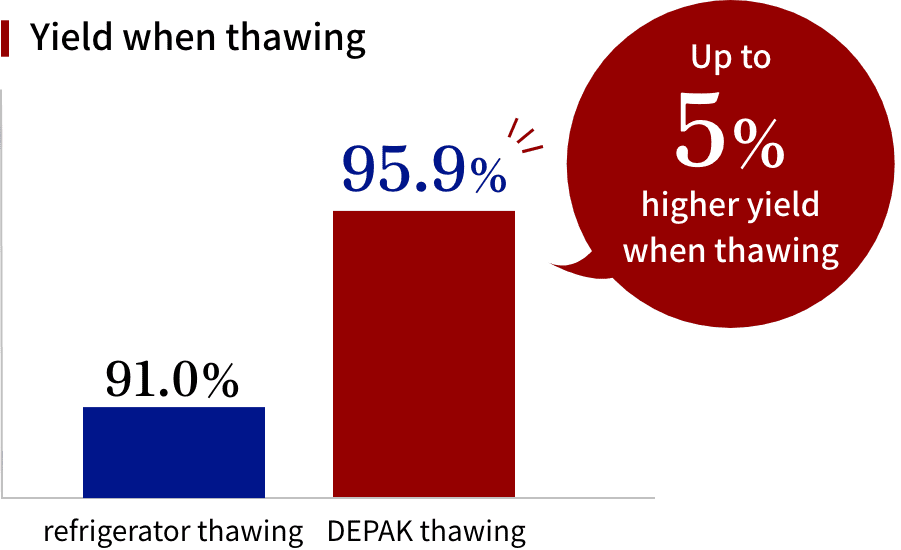

Improve Yield and Quality of Food Ingredients

Improve Yield and Quality of Food Ingredients

Our proprietary “DEPAK” technology thaws each cell evenly, preventing cell tissue breakdown and minimizing the amount of drip loss during thawing. Food can be thawed while maintaining its freshness for a long period of time, and an improvement in yield during thawing can be expected. By reducing food loss, we contribute not only to delicious food but also to improved business management.

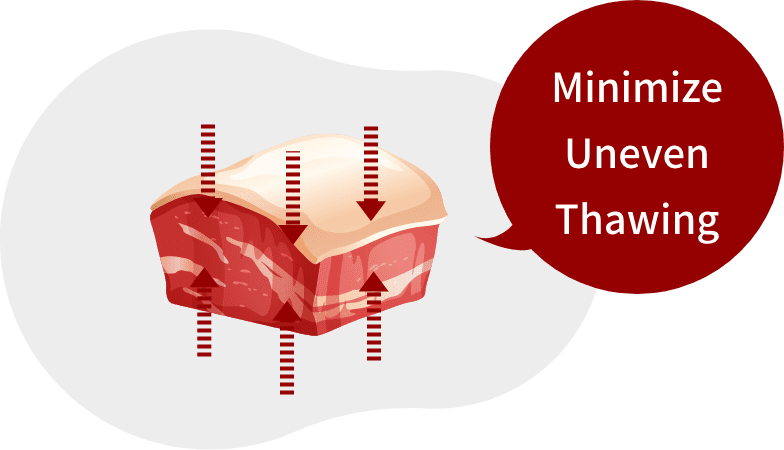

Uniform Thawing for Greater Efficiency

Uniform Thawing for Greater Efficiency

With conventional thawing methods, thawing is done by gradual heating, which inevitably results in uneven thawing. Uneven thawing leads to the expansion of water in the cells, resulting in damage. We have done extensive research in the pursuit of efficient heat exchange. By controlling the temperature and airflow with DEPAK, differences between the center temperature and surface temperature of the food are minimized, enabling even thawing all the way to the core.

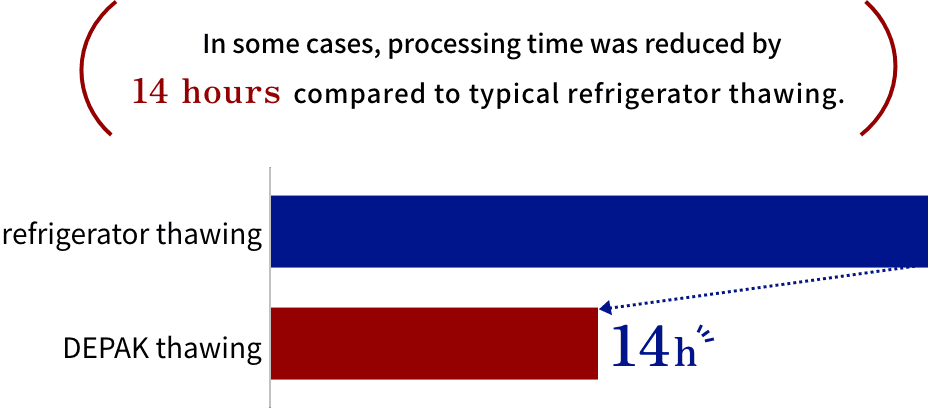

Shorten Thawing Time

Shorten Thawing Time

DEPAK thawing promotes thawing with calculated temperature and airflow while reducing the temperature difference between the surface and center of the frozen food, thereby greatly shorten thawing time without loss of flavor.In addition, it automatically switches to freshness preservation mode after thawing is complete, so there is no need to transfer the food from the thawing machine to a refrigerator. It contributes to a reduction in not only thawing time, but also labor costs.

Ability to Propose

The optimum conditions for ingredients and the equipment to be used will vary depending on the type of food, the amount of food processed, and the type of work in the next process.

We first listen to the concerns of our customers and focus on providing the best solution for usage, placement, and combination. Please feel free to contact us.

-

Solutions

We work to provide the best possible integration of our products by offering proposals based on on-site surveys and workflow.

-

Teamwork

Each department works together to deliver the best possible result our customers

-

LABO

We collect design and research data in our LABO to support innovative future product development.

Products

-

Thawing

Thawing with DEPAK brings out the best taste in food, contributes to a reduction in yield loss and cost.

view more -

Freshness Preservation

Freshness preservation using DEPAK enables long-term storage and improves the taste of ingredients. It reduces food loss and contributes to stable inventory management.

view more

There are a wide range of products for purposes from private storage to large-scale products for factories.

Contact usCase Studies

We have clients among a wide range of companies and industries.

New Case Studies

In addition to large-scale facilities such as food processing plants, we have a wide range of customers including privately owned restaurants.

Contact usNews

-

Case Studies

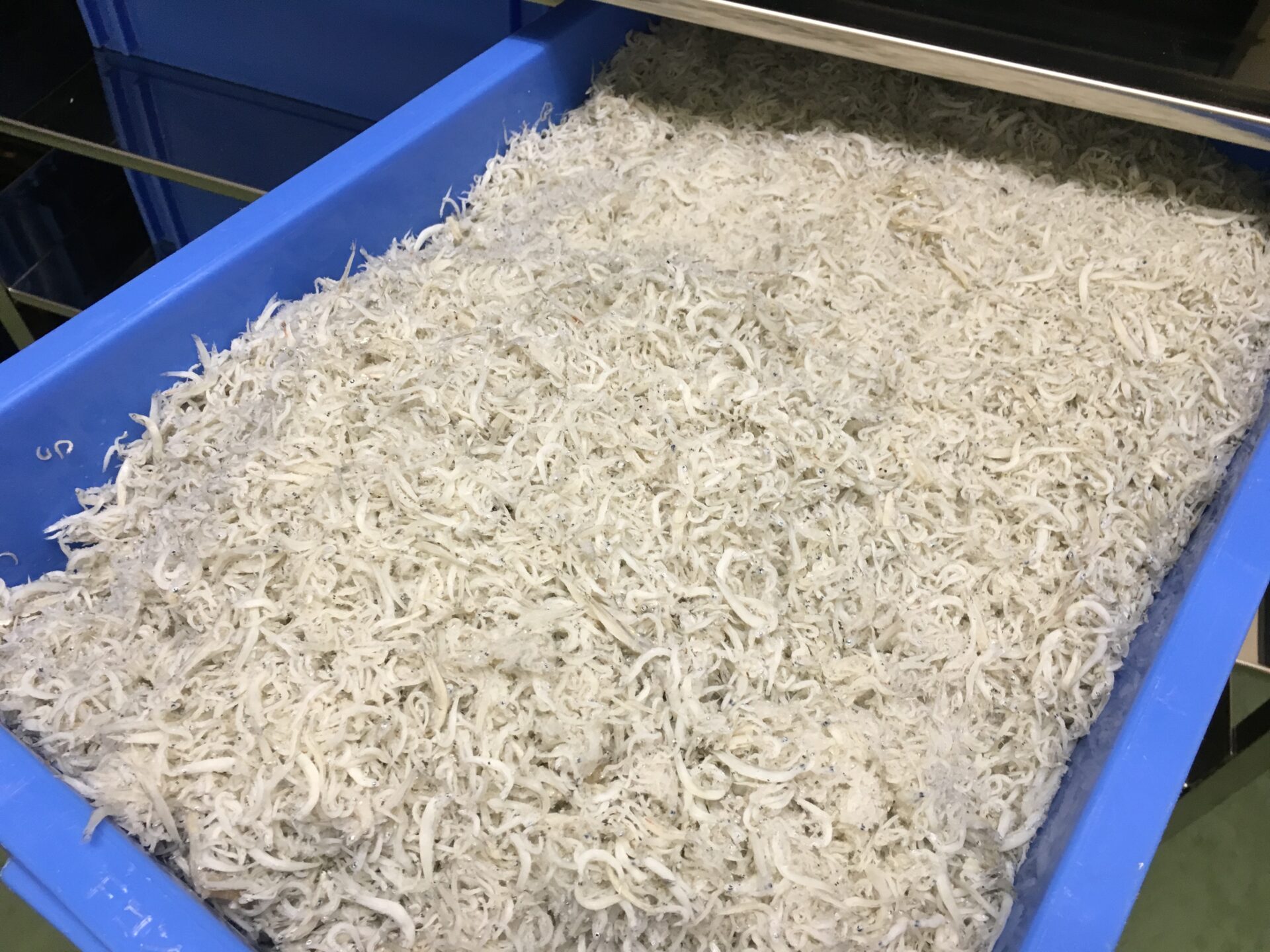

Thawing whitebait

Takahashi Syoten -

Case Studies

Freshness preservation and beef aging

Udonbashin -

Case Studies

Keeping all kinds of food fresh

Tabarusaka (Japanese restaurant) -

Case Studies

Thawing frozen chicken, pork, beef

Toobu Ltd.