Applications

Gunji Yoshikazu Shoten Ltd.

Installed device

thawing machine(SCMTurbo)

Problems

- Reduce discoloration and drip loss

- Improve yield

- Improve operation

Background

To improve thawing quality

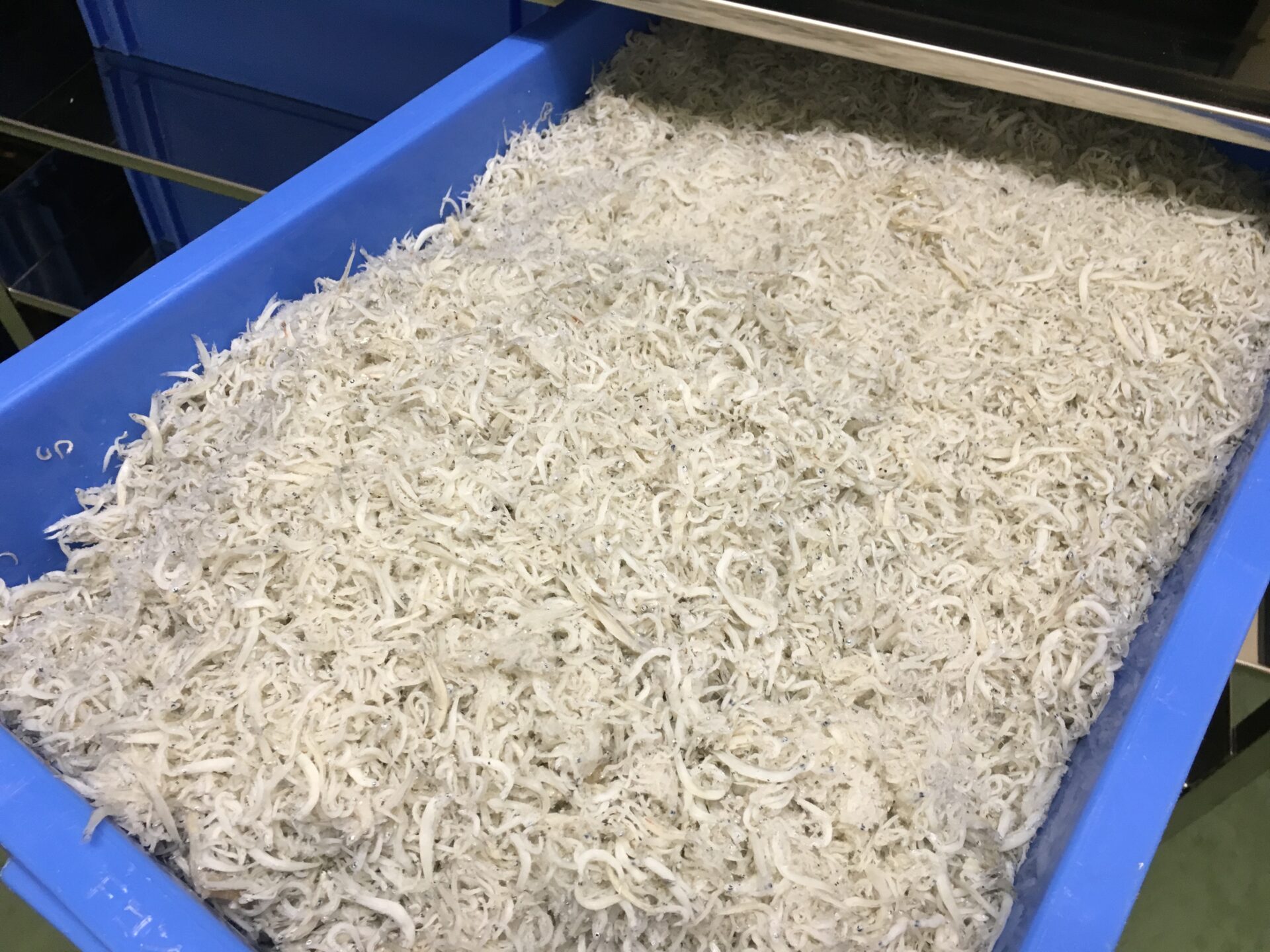

We purchase dressed meat and sell them after thawing by request.

Initially, we thawed in a refrigerator or under running water as needed, but at times we received complaints about discoloration and drip loss, so we decided to install the thawing machine to improve thawing quality. We did a trial with three companies and compared them.

Based on the trials, we decided on Santetsu because the DEPAK thawing machine had by far the least drip loss and thawing time was shorter. We mainly use for thawing thick beef.

Effects

No more complaints from customers and improved yield

Before, the color of meat deteriorated and there was drip loss, but these problems have been eliminated since we started using DEPAK.

We have noticed there are no more complaints, and the thawing quality has improved.

Furthermore, there used be a lot of meat volume loss as it was reduced due to drip loss and discolored parts that had to be thrown away. Since we installed DEPAK, there is no more drip loss and we don’t have to throw meat away due to discoloration, so I noticed that our yield has improved.

We highly recommend this DEPAK machine to anyone who handles frozen meat.

Unexpected benefit of improved operations

Originally, we introduced it to improve thawing quality, it has also been quite useful from the standpoint of operations.

Previously, we had been thawing in the refrigerator, which took up to a week, making it impossible to schedule other work. It was difficult to accept urgent orders because we didn’t know when the thawing process would be finished. And sometimes we lost customers because they could not cut the meat as the core of the meat was still frozen. If we had to thaw the meat in running water hurriedly, the quality would deteriorate. So, it was so difficult to maintain thawing operation. However, since the thawing time is fixed after we introduced DEPAK, it is clear when to start the thawing process depending on the order. We can make necessary arrangements depending on the order. Even if an order comes in suddenly, we can respond to it by saying ‘We can have it ready tomorrow!’ We are now able to respond to customer requests without missing a beat. Although we introduced this thawing machine to improve the quality of meat, we have seen considerable benefits to operations at the site.

Data

We are a company engaged in meat processing, meat product manufacturing, and prepared foods manufacturing. We can meet all your meat-related needs from small to large orders, by purchasing dressed meat and cutting, seasoning, and cooking it to order.

Gunji Yoshikazu Shoten Ltd.

321-166 Minamiakada, Shiobara-shi, Tochigi